Greetings and welcome to our latest newsletter!

We are thrilled to bring you an in-depth look at the exciting developments and achievements here at Techlam. Our team has been hard at work expanding our processing capacity, enabling us to better meet the growing demands of our projects and clients. Among our latest endeavours are several innovative projects that highlight our commitment to quality and excellence.

In addition to our project updates, we’re eager to introduce some exceptional new members who have recently joined our team. Their skills and fresh perspectives are valuable additions to our Techlam family, and we’re confident they will help us drive our success even further.

As we move into November, we’re launching an exciting promotional campaign that we believe will offer significant value to our clients. Keep an eye out for details, and don’t miss the opportunity to take advantage of these exclusive offers.

On the economic front, the Reserve Bank’s recent decision to cut the Official Cash Rate by 50 basis points is a positive development for New Zealand’s economy. This move is expected to alleviate financial pressures on both businesses and households, and we’ve already started observing a wave of optimism in the markets. We are hopeful that this positive trend will continue as we approach the end of the year.

Thank you for taking the time to catch up with us. We appreciate your continued support and engagement. Please feel free to reach out if you have any questions or require further information about our projects or promotions.

Stay safe and take care.

Brett Hamilton – Managing Director

// CNC technology transforming glulam production at Techlam

Last June, we announced that our new CNC 6 Axis Machine, the Oikos XL manufactured by SCM in Italy, was fully operational and had started processing its first jobs. For five months now, this machine has been a game-changer for Techlam, and here’s why it matters for our business partners and customers.

“The CNC machine has drastically reduced our production time,” says Jason van Ossenbruggen, Techlam’s Detailing Team Leader. “Complex beams that used to take us many hours to produce can now be completed in just minutes with the CNC. This increased speed allows us to meet tight deadlines and deliver projects more efficiently.”

“The additional capacity has drastically reduced our production time”

The Oikos XL allows Techlam to automatically manage and process massive engineered timber elements weighing up to 4000 kg with cross-sections up to 1250 x 500 mm.

The machine’s 6-axis machining head can access all six sides of a glulam element without needing to reposition it. This eliminates time-consuming manual handling and ensures every cut is made with absolute precision.

“The accuracy of the CNC is unmatched,” adds Jason. “It eliminates the potential for human error, ensuring every cut and detail is perfect. This translates to higher-quality products and a smoother construction process for our clients.”

“The accuracy of the new line is unmatched”

The new machine centre is a key component of Techlam’s ongoing sustainable manufacturing project. “A huge percentage of our glulam will be going through this centre, and anything the CNC’s are unable to process, will be completed by our team of skilled carpenters,” details Brett Hamilton, Techlam’s Managing Director.

“Beams are loaded in one end of the machine, and it will process them, cut them, slot them, drill them, label them, all to 100% accuracy. The product is delivered to site, ready to install, and that makes it so much easier for our clients, especially on some of the remote sites where labour is not always readily available.”

“By significantly increasing our production capacity, we’re aiming to boost overall production by more than 30%.”

“This investment allows us to take on larger and more complex projects,” explains Brett. “It also means we can better serve our existing clients by reducing lead times and offering more competitive pricing.”

Sustainability is at the heart of what we do here at Techlam. From automatically selecting the best tool for the job to planning the most efficient cutting path, the CNC machine’s precision ensures maximum productivity and minimal raw material excess.

“We’re committed to minimising our environmental footprint,” shares Brett. “The CNC machine not only reduces waste but also optimises material usage, contributing to a more sustainable construction industry. It has already made a huge difference in the prefabrication department.”

“Our processing capacity is a key component of Techlam’s ongoing sustainable manufacturing project.”

Since its commissioning in May, the CNC machine has already processed over 100’s of m³ of glulam for various projects, including the new Wynyard Quarter (Auckland), Kowhai Falls Retail Centre (Warkworth), Tuckers Beach Wildlife Reserve (Queenstown), and the Tāwhaki National Aerospace Centre’s new aircraft hangar (Canterbury).

The diversity of these projects showcases the versatility and efficiency of our CNC machine in delivering high-quality glulam solutions for a wide range of applications.

The additional CNC capacity marks a significant milestone in Techlam’s journey. We’re excited to continue leveraging this technology to provide our clients with innovative, sustainable, and high-performance glulam products.

Interested in learning more about how our processing and glulam solutions can benefit your next project? We’d love to hear from you!

// Shaping the future with glulam timber innovation

We believe in blending traditional craftsmanship with cutting-edge technology. Our expertise goes beyond simply supplying high-quality glulam timber. We offer a complete suite of services, from design and engineering to manufacturing and installation. This allows us to partner with our clients throughout their entire journey, ensuring their vision is brought to life with precision and efficiency.

A recent example of our capabilities is our collaboration with Jackson Orchards. We were tasked with replicating the iconic curved timber design of their original packhouse for a new extension. This presented a unique challenge, as the original design by Michael Wyat in 1989 featured striking curved laminated timber beams that were difficult to source after so many years.

“Techlam offers a complete suite of services, from design and engineering to manufacturing and installation.”

We rose to the occasion, leveraging our deep understanding of glulam technology to recreate the original beams with remarkable accuracy. Working closely with the architectural and engineering teams, we provided 3D modelling and detailed shop drawings to ensure a flawless fit. The result is a seamless extension that perfectly complements the existing structure, showcasing the enduring beauty and versatility of timber.

Kevin Jackson, the owner of Jackson Orchards, was thrilled with the outcome. “When the beams arrived, they were beyond expectation,” he said. “I couldn’t believe it myself how perfect and grand everything looked.”

“When the beams arrived, they were beyond expectation. I couldn’t believe it myself how perfect and grand everything looked.”

At Techlam, we believe in working closely with our clients and partners to deliver complex and bespoke solutions that meet their unique needs.

Whether we’re crafting bespoke solutions for architectural masterpieces or providing readily available products through our network of timber merchants, including Carters, Placemakers, Mitre 10, Bunnings and ITM, we continue to inspire and enable the creation of beautiful, functional, and sustainable spaces.

Inspired by what you’ve seen?

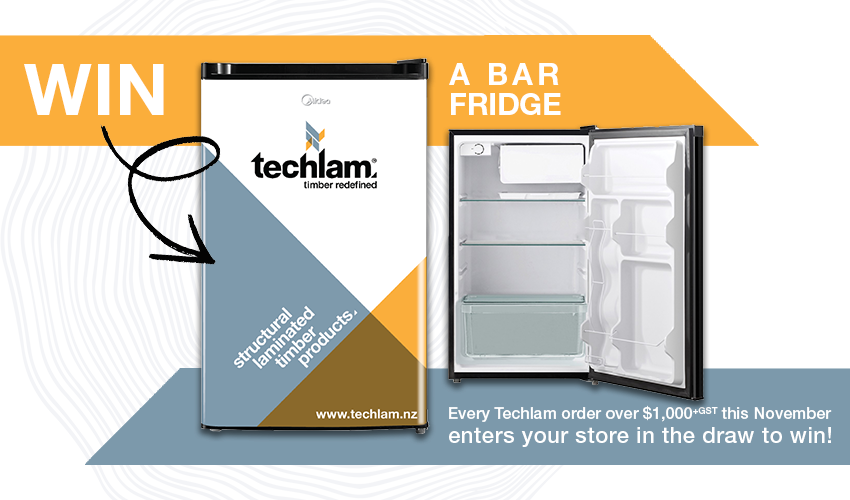

// Techlam’s November Merchant Promo

This November, Techlam is giving away a branded bar fridge to one lucky timber merchant!

You’d like to enter your store in the draw to win?

// Staff update

We recently welcomed three talented individuals to the Techlam team! 🎉

- Lola Aubert joins us as Marketing Manager, bringing a decade of experience and a passion for the primary industries and the manufacturing sector.

- Jodi Chappell takes on the role of Office Manager, with over eight years of experience and a commitment to outstanding service.

- Dorothy Chung joins as our BIM/CAD Technician, bringing a global perspective and expertise in construction processes.

Welcome aboard!